全息实业

- English |

- 中文 |

- Русский язык

-

-

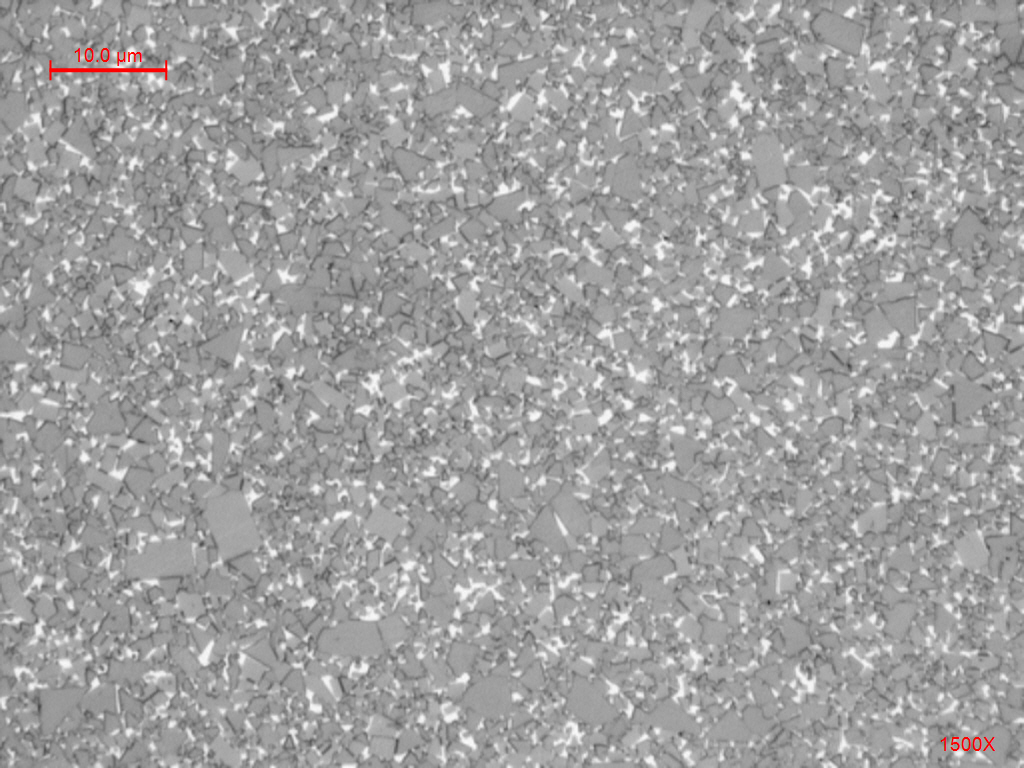

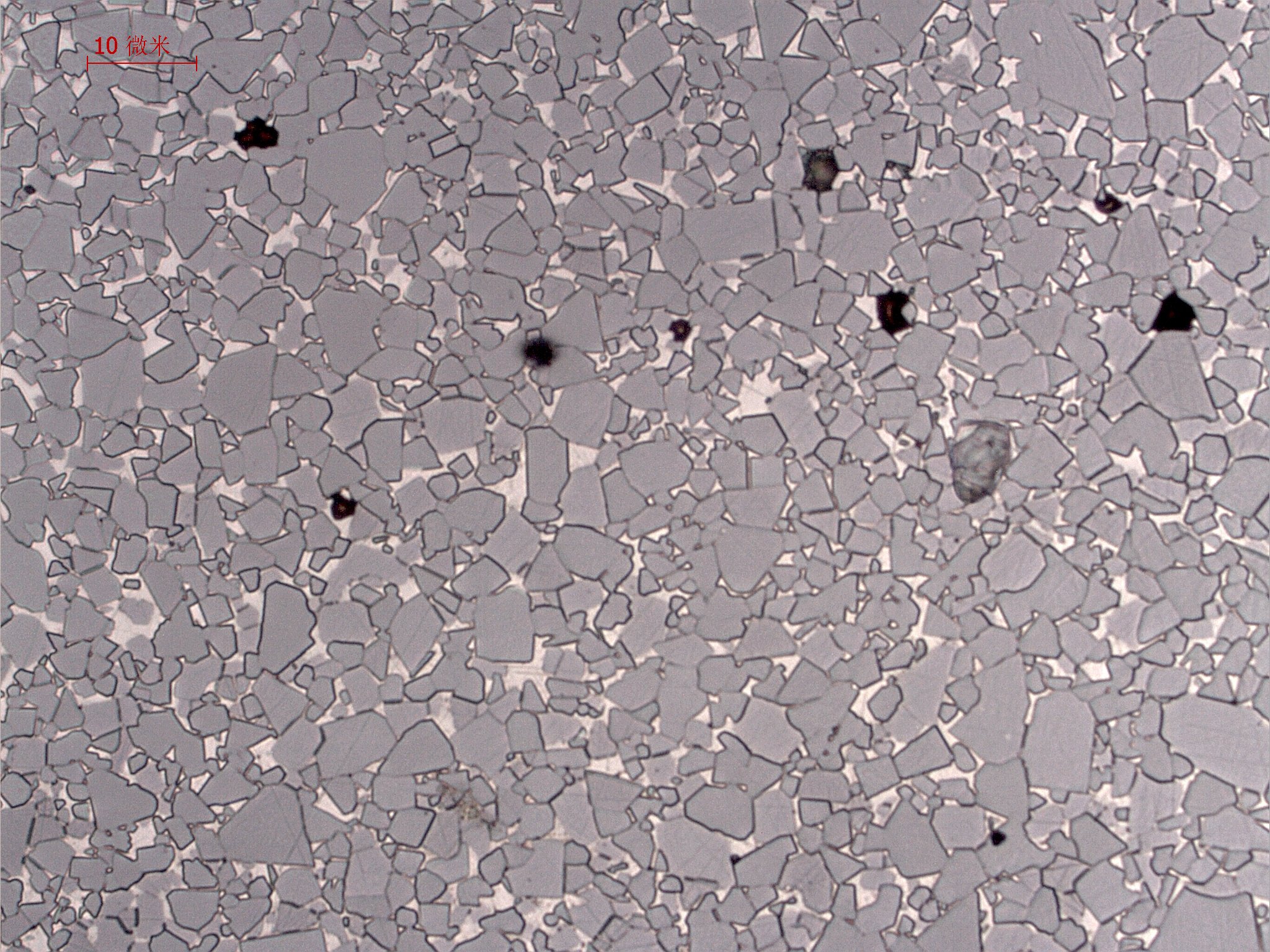

GOOD METALLOGRAPHIC STRUCTURE

-

-

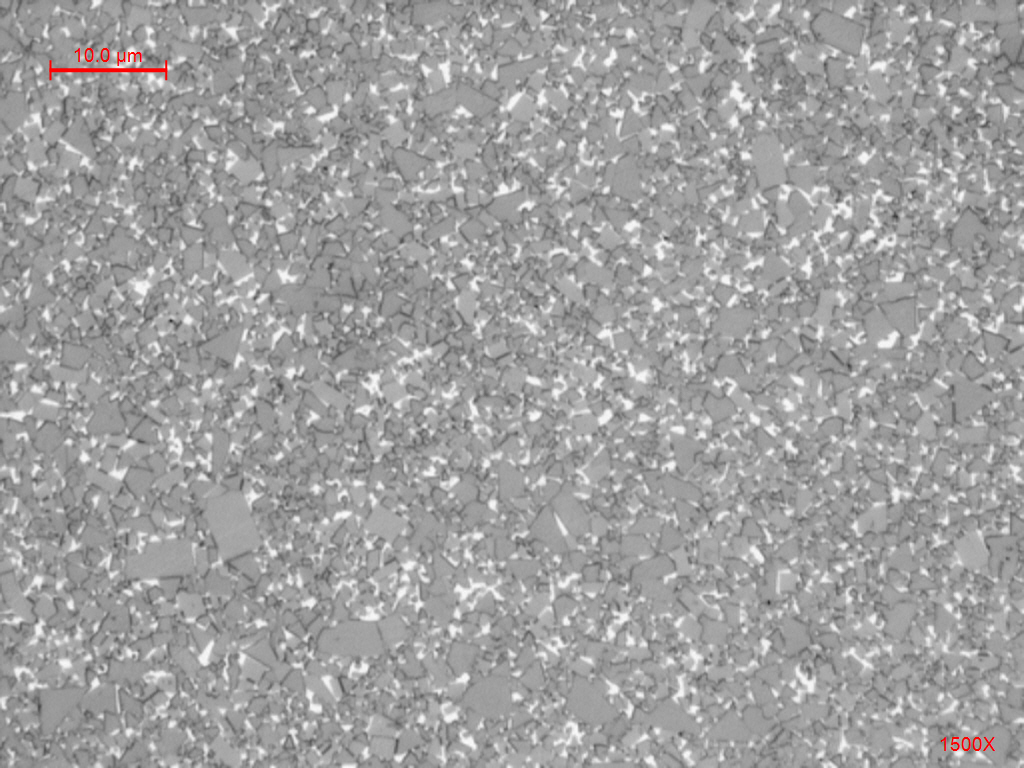

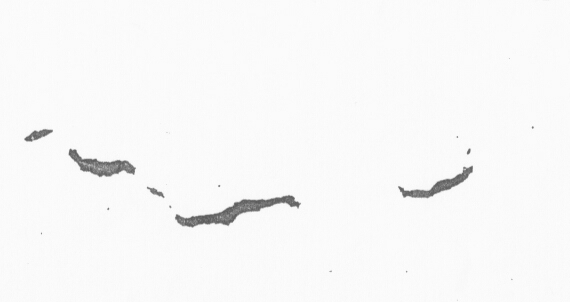

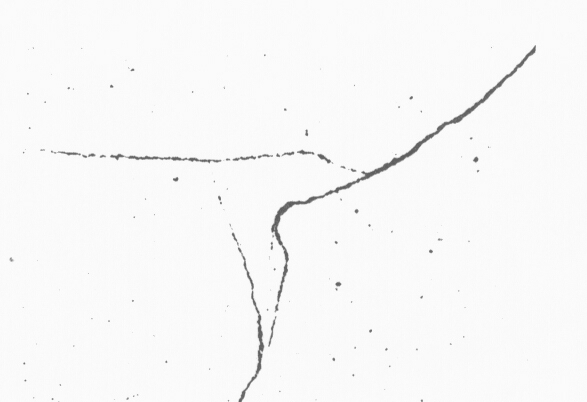

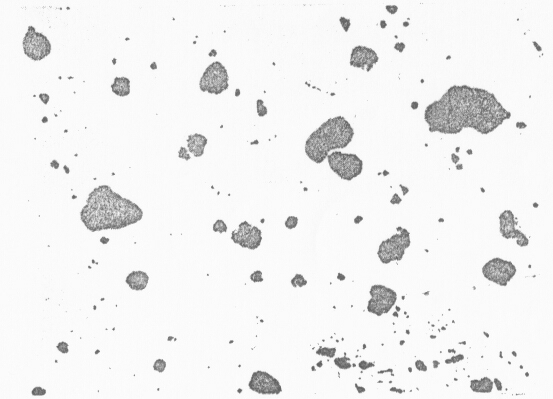

BAD SINTER STRUCTURE

-

-

BAD SINTER STRUCTURE

We believe the quality stems from inside,river comes from many drops.

Cases analysis

Case 1.

According to a customer’s need, we produce tungsten carbide square shape tool for him, it is an easy processing product,however,the buyer is a trade company and know little about tungsten carbide.First time we offer 2 pcs samples ,and the feedback is our sample performace is not as good as end-user’s past product.After receiving customer’s sample,we test it and edit the raw material brand,degree of accuracy,hardness index ect. ,and deliver 2pcs new samples to buyer by express,then begin 200pcs small trial order. During that period, the general raw material price increases sharply, during 4 months about 15% up,and for some special powder price about 20% up. After trial order of 200pcs, the customer continue to place order and both sides negotiate the price iuuse again as there is no confirmed long-term contract between us at that time;

Caes 2.

An engineering company applys the choke valvs in site,successively there appeared internal tungsten carbide head brittle fracture, or the tungsten carbide head falls off from the rod, causing the throttle channel blocked. Received field personnel and valve manufacturer feedback, our engineers and cooperation research institute research the situation according to the working conditions,then revise the material and some processing technology. After new tools are applied, the results are good and the above situations never happan again, moreover, ven the stem life is improved by 2.5~3 times compared wuth the normal ones.

Case 3.

An engineering company purchased Cameron plug & cage choke valves, the tungsten carbide plugs corrode much during less than 2 years’ application, there is clear rugged surface erosion.Through the failure parts micro analysis combined with the working conditions consideration, the WP is very high and the corrosive gas flow speed is high, causing great erosion. We took some new measures,and made the new tungsten carbide plugs and other trims specially, and offered some other suggestions. After replacing the parts, the working life is increased by more than 1.5 times;

Case 4.

In a hydropower station,the ball valve problem affected the normal power generation and supply. Considering the alternating wet and dry environment of hydropower station, water quality and sediment concentration etc working conditions, we make tungsten carbide hard surfacing for ball body, water seal ring and gasket ring, also offer some technology processing suggestions to some joint parts.In this way the ball valves improve the wear resistance of the sediment, prolong the woirking life, improve the flexibility of the pistonm and reduce the cost;

Case 5.

A nuclear research institute affiliated factory apply OSG CPM taps for a long time, however, some work piece is very hard to process, for example they produce a kind of special tool for Halliburton,the reject rate is as high as 60~70%, also causing tool cost is very high. After applying our tungsten carbide tap ,the tool cost decreases about 50%, the tapping efficiency improves 40%, and labor cost is reduced too.